Instruction division utilizes 3D printers a great deal. From straightforward and modest FDMs to the most complex metal printing gadgets. Educating, testing, printing a great deal. Those gadgets should be straightforward, moderate, innovative and simple to fix.

Piotr Dudek is a subordinate educator at AGH University of Science and Technology. He runs an added substance producing lab furnished with a wide range of 3D printers. From FDMs, by means of SLA, to powder and SLS gadgets. The Branch of Manufacturing Systems in the Faculty of Mechanical Engineering and Robotics has immense added substance fabricating needs. The primary fields of his scholarly advantages are fast prototyping and figuring out. In his lab, 3D printers are utilized by both logical specialists and understudies. The scope of utilizations begins with understudy tasks or ace’s theory and leads logical examination papers and material tests.

From various added substance fabricating innovations Dudek is particularly intrigued by specific laser sintering (SLS) printers. There are a few reasons.

First of all in Quite a while innovation you can print practically any shape, without stressing over confused math – says Piotr Dudek.

The opportunity of creation is particularly significant. Regardless of if the inner or outer structure of the component is co-founded. His workforce as of now utilizes a few SLS 3D printers from EOS, Zcorp and Sinterit.

The advantages of huge machines are associated with their amazing print volume. On the off chance that you need large parts printed on the double it is elusive different arrangements. However, there are likewise drawbacks as significant expense, troublesome alignment and the need of exceptional preparation for administrators. It is likewise pricey to print little parts, as you have to give a great deal of powder to begin printing.

We are utilizing the enormous EOS SLS 3D printer for quite a while and we needed to contrast it and Sinterit Lisa, check the conceivable outcomes of it – says Piotr Dudek. In SLS innovation everything about. The temperature of the printing chamber, powder circulation framework, warming or laser moving instrument are exact and significant highlights. We needed to test if Sinterit’s gadget is a significant arrangement. – includes Dudek.

One of the frail purposes of the large machines is that the galvo laser guiding framework could be effectively discalibrated during the transportation. Sinterit Lisa printers use a gantry framework so the printer could be pre-aligned, which implies that in the wake of removing it from the container you don’t have to go through days of alterations.

Another advantage is that you can use as meager as a couple of liters of the powder to begin printing. It is a way less expensive arrangement, particularly at colleges, where you print a variety of models for countless understudies and scholastics and it isn’t conservative to print them independently on a major gadget.

Managing various materials

Propelled SLS clients print from different gatherings of materials, with various dissolving points. It is essential to deliberately clean the printer while changing the material. In little gadgets it is a simple procedure, taking not longer than 30 minutes. In large machines in some cases you have to go through a few hours and arriving at all corners can be troublesome.

Understudy well disposed

3D printing resembles riding a bicycle. You can’t do it thoroughly while somebody is holding you despite your good faith. Simply envision letting understudies take a shot at a gadget worth in excess of 250 000 USD all alone. I don’t know whether it is even worthy of the purpose of a guaranteed administration. With work area measured gadgets for under 10 000 USD the hazard is way lower. It is additionally more straightforward being used, so following a short, one hour instructional course, researchers can print without the outer assistance. The more understudies can master utilizing proficient innovation the better their future ventures will be. At the college as well as generally available they will join after graduation.

About Sinterit

Sinterit is the principal maker of work area specific laser sintering 3D printers, with a crucial quicken the world’s improvement by giving everybody access to imaginative 3D printing SLS innovation. It centers around convenience, flexibility and accessibility, with the goal that tomorrow can happen today.

Why do Universities need little SLS 3D printers? Correlation with enormous SLS

0

SHARES

6

VIEWS

Leave a Reply Cancel reply

Stay Connected test

- Trending

- Comments

- Latest

Manish Goyal: Revolutionizing Investment through Multibagger Securities

September 18, 2023

Multibagger Securities: Maximising the Wealth of Clients

December 19, 2021

Lindsey Myers: Pioneering Paths in PR Excellence

March 5, 2024

Most Influential Business Leaders to Look Out In 2024

February 13, 2024

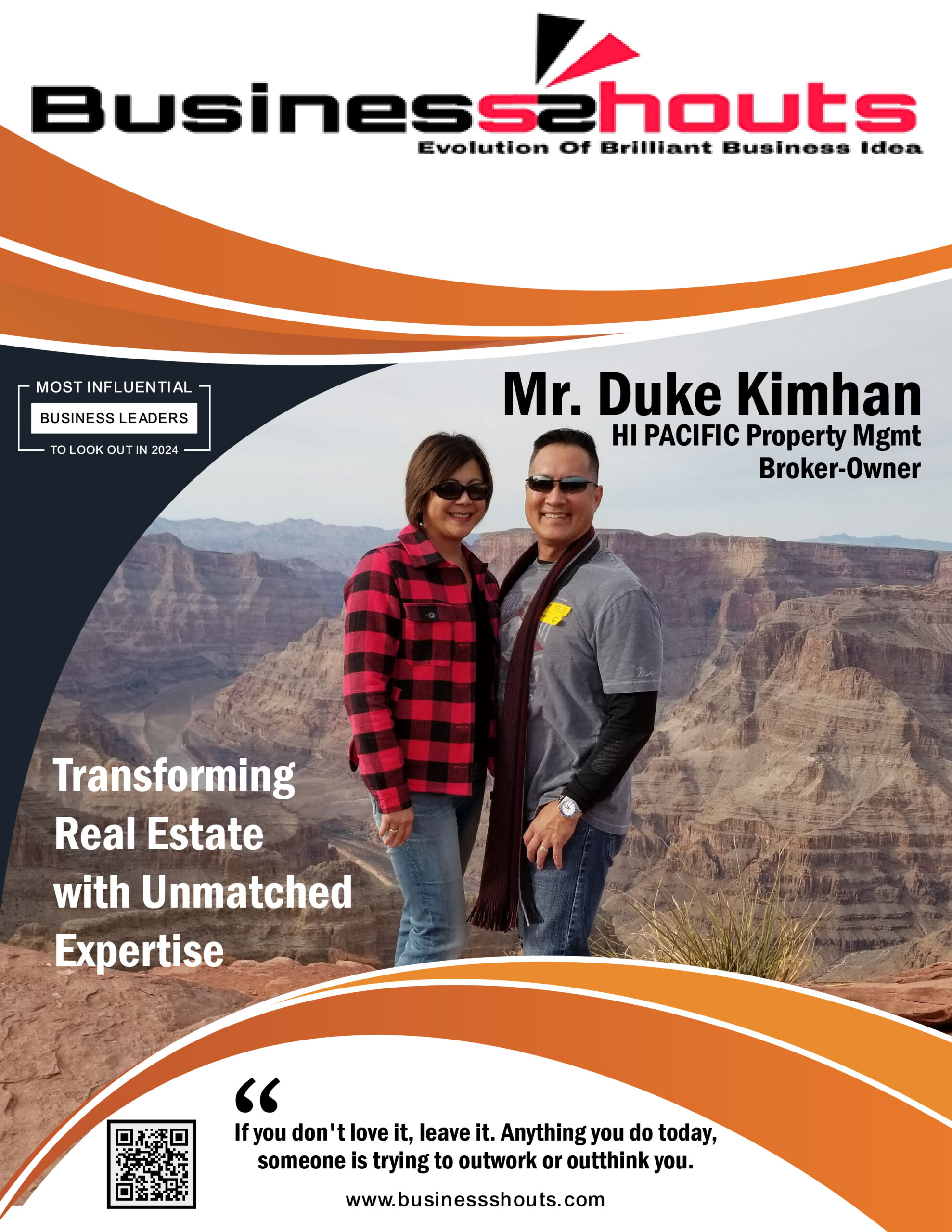

Duke Kimhan: Transforming Real Estate with Unmatched Expertise

February 20, 2024

About Us

Business shouts is determined to delineate the accomplishments of organizations and business people as well as to reveal insight into the advancements they are conveying to upset the current market situation. Doing as such, we would like to motivate and illuminate a huge number of organizations and work force far and wide through our best administration magazine.

Copyright © 2021 By BusinessShouts | All Rights Reserved.